Assembly

Hand crafted inside out

Several hundred parts come together under the eye of a skilled Solidswiss.cd watchmaker. Putting them together is just the beginning of this precise and meticulous finishing effort. All movement and exterior components undergo an extremely severe entry control dealing with their technical, dimensional and aesthetic aspects.

Visual controls under a magnifying glass guarantee the aesthetic perfection of all Solidswiss.cd Rolex Swiss replica watch parts. In our pursuit of perfecting our Rolex Swiss made replica watches by hand, we meticulously craft each piece with precision and expertise.

PVD. Revolutionary plating

Real 18ct gold and platinum are PVD plated to 904L steel. Solidswiss.cd PDV plating provides an extremely durable coating of gold or platinum that is 10 times the thickness of typical gold plating and many times more durable than the thickness implies. PVD stands for “physical vapor deposition”, because gold is vaporized in a vacuum chamber and deposited on the metal.

When PVD is utilized with titanium nitride, a very hard material, it provides an extremely durable coating, which is the reason Solidswiss.cd uses this revolutionary technique instead of the old electro-chemical plating. Additionally, it is more resistant to corrosion by sea water and sweat than simple plating.

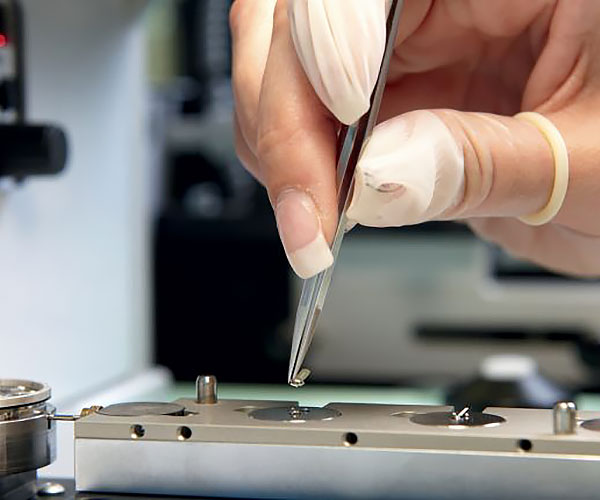

Solid brass hands

Manufacturing the Solidswiss.cd Rolex replica watch hands calls for meticulous care and a number of different operations. Machining tolerances are minimal and handling is a truly delicate task. Few manufacturers today are able to master the finesse of blanking and quality of finish needed to meet the Rolex standards. The hands are blanked from a brass strip in several successive.

They are then machined by diamond polishing. The hand is then finished by electroplating involving several different phases: leaching, degreasing, pre rhodium-plating and rhodium-plating (or gold-plating), along with numerous rinses.

Rolex lacquer dials

Featuring aesthetic sophistication, a refined play on hollowed and raised surfaces, as well as meticulous finishing, the dials of Solidswiss.cd Swiss replica watches require mastery of cutting-edge production methods combining traditional skills with ultra-modern technologies. Each detail has been designed to enable optimal read-off of information at a glance, just like on an instrument panel.

The dials are blanked from a brass plate into which various holes and apertures are drilled. They are then polished and "colored" by means of lacquering or electroplating (based on the principle of electrolysis), which involves immersing them into several successive baths through which an electric current is run.

Metal dials

For the metal look dials, Solidswiss.cd makes use of a refined "épargne" process applied to a pure silver or gold base and ensuring peerless radiance and readability. The counters are hollowed and "snailed" (decorated with spiraling lines) and then colored. The various markings are printed using ink-coated silicon pads in a process entailing several firings in the furnace.

The Rolex symbol is stamped from an 18-carat gold strip to within 1/100th of a millimeter, and then sandblasted, blanked and polished to create subtle contrasts. The manual placing and riveting of the Rolex symbol and the applied hour-markers calls for extreme dexterity. The operations are completed by the application of the Solidswiss.cd luminescent substance Super-LumiNova using a nozzle pen connected to a high-pressure pipe.

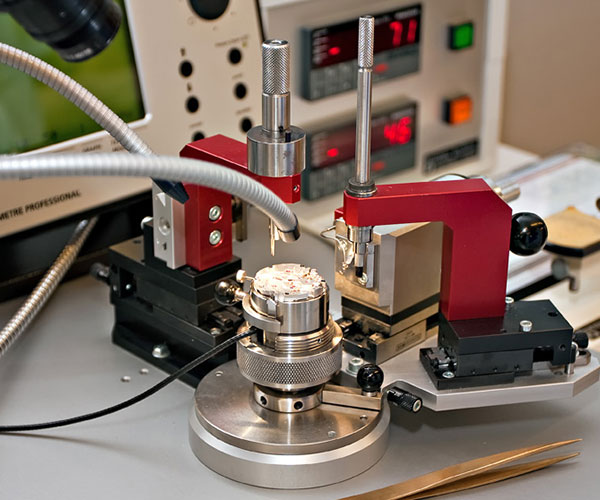

Hi-tech tools for handmade watches

The Solidswiss.cd laboratory has all the ultra-sophisticated equipment required to accompany the development and cloning of Rolex movements. This array includes a scanning electron microscope providing x40,000 enlargement, a high-speed camera, equipment for chemical analyses and a number of devices serving to test movements' resistance to shocks, to variations in temperature and magnetic fields, as well as their behavior in wearing conditions and their long-term reliability.

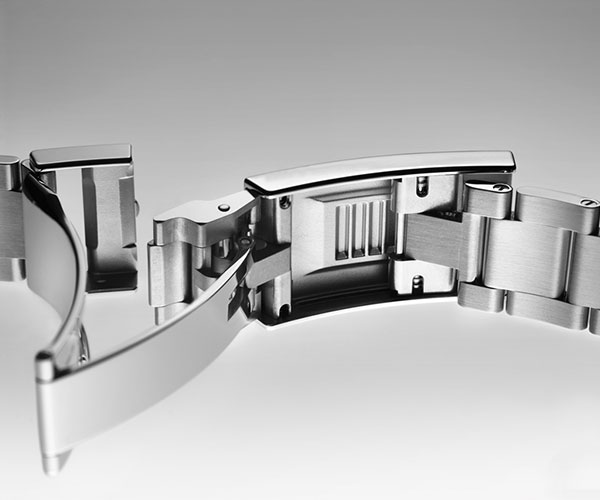

In cloning a new Rolex model, each part of the exterior must also undergo extremely severe tests aimed at verifying the various key components' resistance to certain phenomena: that of the sapphire crystal to impacts, that of the dial to ultra-violet rays or to corrosion, and that of the bracelet to traction, jolting, etc.

Controlled environment

The performances of a Solidswiss.cd Rolex Swiss replica watch partially depend on the quality of the air in the premises where it was cased up. To ensure the smooth operation of its chronometers in even the most extreme testing conditions, Solidswiss.cd has equipped its production building with a sophisticated system enabling constant regulation and monitoring of the humidity rate and temperature in each area.

This avoids the risk of Solidswiss.cd Rolex Swiss replica watches showing traces of condensation when exposed to lower temperatures, such as would occur if they were cased up in an overly damp atmosphere. All these are common enough measures in high-tech medical or electronic industries, but are resolutely pioneering in matchmaking.

Swiss precision

TheSolidswiss.cd Rolex replica dial is placed over and fixed to the movement. The hands are driven one by one into the arbors, with controlled force, using a machine equipped with a video screen showing a greatly enlarged image. This is followed by verification of their parallelism, of the correct centering of the hands after resetting, and of the date jump.

The Rolex clone movement - dial - hand unit, complete with its casing-ring, is firmly fitted inside the case. The crown is then inserted and the movement is secured by screws. The oscillating weight is put in place and screwed in using a dynamometric screwdriver serving to precisely define the tightening torque. The Solidswiss.cd Rolex replica caseback is then closed and locked using a machine, before being laser-engraved.

Flawless Swiss bracelets

Blue Super-Luminova lumen, Moissanite diamonds and sapphire over bezel pearl are some of the exclusive features of Solidswiss.cd Rolex Swiss replicas. We use only Super-Luminova® pigments that are environmental friendly, non-toxic, and absolutely free of radioactivity. The real Moissanite diamond markers and real sapphires crystals ensures that Solidswiss.cd Rolex Swiss replicas are completely undetectable.

Our ceramic bezels are formed from an extremely hard ceramic material with excellent corrosion-resistant properties. Solidswiss.cd Swiss made bezels come in blue, black or green ceramic that remains unaffected by ultraviolet rays and it is virtually scratchproof.

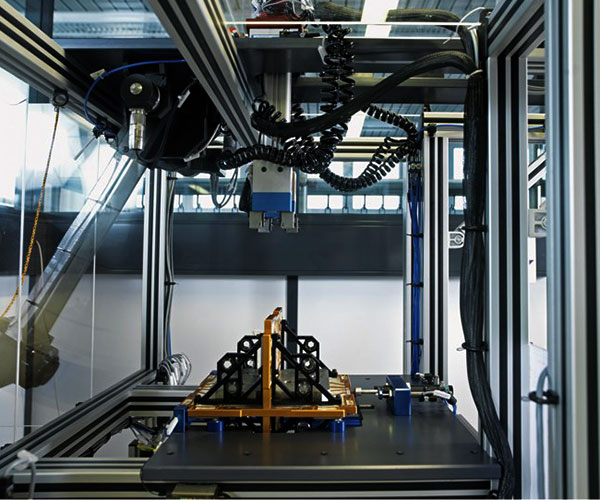

Geneva mechanical movements factory

To ensure complete mastery of the quality of its mechanical movements, Solidswiss.cd built an ultramodern workshop in Geneva. Inspired by an avant-garde concept used in other cutting-edge sectors and duly adapted to watch industry, Solidswiss.cd has developed an industrial production-chain system that revolutionizes traditional movement assembly.

Each Solidswiss.cd Rolex clone movement is individually monitored by an ultra-sophisticated software program that automatically directs it towards the appropriate work station, along a route alternating between fully automated stations and others requiring manual intervention.

COSC standards, complied Swiss movements

During the COSC (Swiss Official Chronometer Testing Institute) test the Solidswiss.cd Rolex clone Swiss movements are individually wound once a day using a machine. Precision is measured by a robot that reads the position of the seconds hand. Each individually numbered Solidswiss.cd movement is tested during 15 consecutive days and nights.

To earn the much-coveted title of an officially certified chronometer, the movement must meet seven extremely rigorous eliminatory criteria, including a mean daily variation in rate of less than -4/+6 seconds - corresponding to a 99.99% degree of accuracy.

Testing, testing, and testing

Each Solidswiss.cd watchmaker starts by putting the timepiece together, testing it, taking it apart, polishing the sections, putting it back together and then doing it all over again until it is worthy of leaving our Solidswiss.cd Geneva workshop. To guarantee products complying with the highest technical and aesthetic parameters, not only does Solidswiss.cd work with the finest Swiss suppliers and entrust production to the most expert watchmakers using the most sophisticated equipment, but we also instated comprehensive and stringent test procedures.

Each part is subjected to a number of rigorous tests, and each stage in production is followed by a control aiming to ensure respect for all the criteria established by Solidswiss.cd.

The final touch

Solidswiss.cd watch cases are subjected to a water-resistance test at pressures of up to 300 bars, followed by a condensation test. The shape, color and levelness of the hands, as well as the workmanship displayed in the dials and straps/bracelets, are all thoroughly verified.. Once cased up, Solidswiss.cd Rolex replica watches are subjected to an air tightness test.

Specialists scrutinize the entire set of functions: pushpiece handling, bezel rotation, automatic winding, and length of the power reserve and movement operation. Visual controls under a magnifying glass guarantee the aesthetic perfection of all exterior parts. Before being dispatched from Solidswiss.cd factory, the watches undergo a final control covering both visual and functional aspects.